If you are looking for reliable dip tea bag packing machine manufacturers, suppliers, and exporters, then there is no other than Foodprocessing-machines, which is the best for this. We are a team of professionals experienced in this field and have complete knowledge of the same.

We know everything about the manufacturing and production process to ensure perfection in the products. Our team closely looks into the complete manufacturing and production process so that the outcome is detailed and perfect in quality.

The best part with us is, you can get everything right, from simple tools, industrial instruments to integrating complex machinery in one place. And all of these are manufactured and produced by field experts.

The Foodprocessing-machines are known as the best dip tea bag packing machine manufacturers, suppliers, and exporters who never miss the deadlines. Yes, our top most priority is always to deliver perfection, high-quality products, and reliable services.

And our team ensures that our motto of the best deliverance, quality, and efficiency is met at every stage of the process so that the final outcome is just what’s desired- satisfactory to the consumer. We use the latest technology, advanced techniques, approved strategies, experienced workforce, and tested approaches to get the best and satisfactory results.

We have been trained under critical situations so that we can handle anything with ease. We know how to manage situations like emergency deliveries, urgent requirements, and bulk orders. Our executives are available round-the-clock to assist you regarding price quotations, order details, customer support, product quality, and other information.

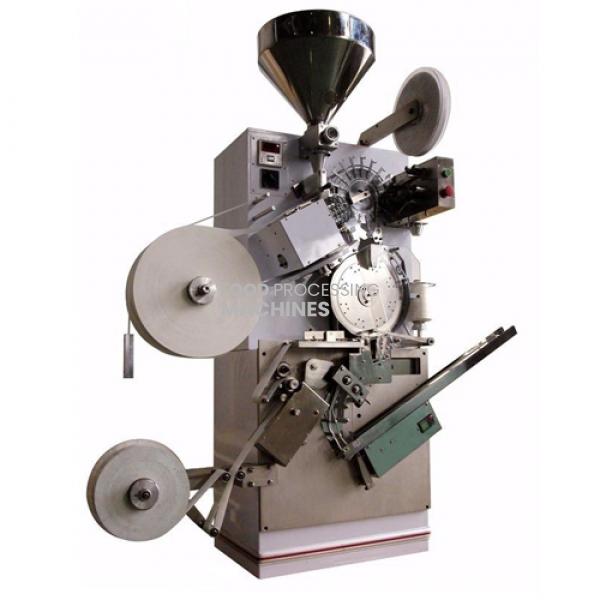

The machine is a new type of heat-sealed, multi-functional automatic

tea bag packaging equipment. The main features of the machine is a

forming inside and outside the bag, to avoid the direct contact with the

staff and improve efficiency. Inside the bag for the filter cotton

paper, can be automatically with a label, the outer bag for the

composite paper. The biggest advantage is that: labeling and outer bags

can be used photoelectric positioning, packaging capacity, inner bags,

bags, labels, etc. can be adjusted, according to the different needs of

users to adjust the size of the inside and outside the bag in order to

achieve the best Packaging effect, improve product appearance grade, so

that product value.

Packing Range: 1-8g/ pouch

Packing Speed: 30 ? 60 bag/min

Roll outer diameter: £Φ350mm

Roll inner diameter: Φ76mm

Air pressure: ≥ 0.6Mpa

Power Supply: 1.4Kw?220V?

Machine Dimension: L830×W660×H1522?mm